Blog

What Machines Does Shoes Use? A Comprehensive Guide to Footwear Production

What Machines Does Shoes Use? A Comprehensive Guide to Footwear Production

The footwear industry, known for its intricacies and precision, has evolved over the years thanks to technological advancements. Machines play a crucial role in ensuring that shoes are produced efficiently and with high quality. From sewing to lasting, various types of shoe machines are used throughout the process to create the shoes and boots that consumers wear daily. This article explores the types of machines used in the shoemaking industry, their roles, and how they contribute to the overall shoe making process.

Introduction: The Importance of Machines in Footwear Production

The production of footwear is a highly mechanized process, relying heavily on machines to carry out various tasks. Whether it’s cutting materials, stitching parts together, or assembling the shoe, machinery ensures that the production line is efficient, precise, and capable of handling large volumes. These machines are particularly beneficial for mass production, ensuring that shoes can be produced quickly without compromising on quality. From small workshops to massive footwear factories, shoemaking machines have transformed how shoes are made.

Types of Machines Used in Footwear Manufacturing

1. Shoe Sewing Machines

Shoe sewing machines are among the most essential tools in the footwear industry. These machines are designed to stitch the various parts of a shoe, including the upper, lining, and other components. Sewing machines in shoemaking are typically heavy-duty to handle the thick, durable materials used in shoe construction, such as leather, fabric, and synthetic materials.

- Role of sewing machines in shoemaking: These machines are used to assemble the parts of a shoe, including stitching the upper to the sole, adding reinforcements, and attaching other essential components like tongue or eyelets.

- Types of sewing machines used in footwear production: Various sewing machines are employed, including walking foot and double needle machines, designed for durability and flexibility. These machines can work with both simple and complex stitch patterns depending on the design of the shoe.

2. Molding and Lasting Machines

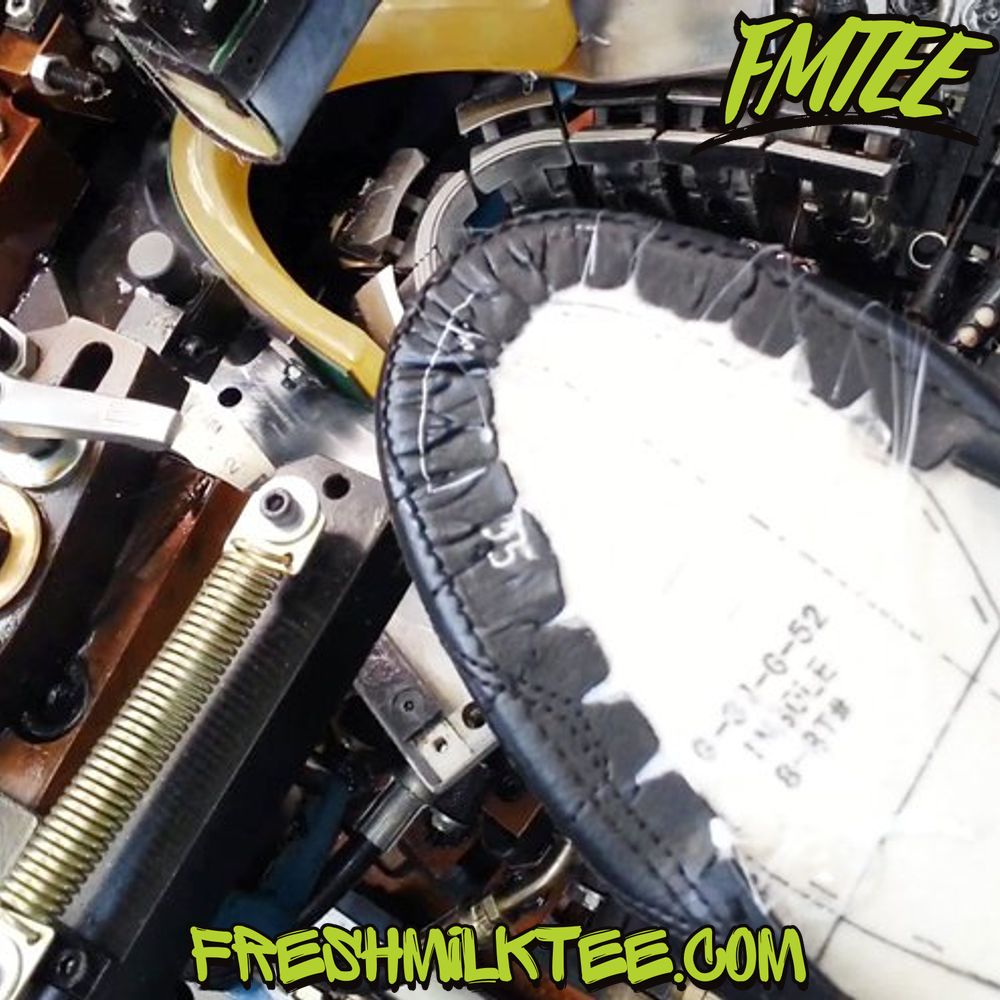

Lasting is one of the most crucial stages in the shoemaking process. It involves shaping the upper part of the shoe around a mold (called a last) to ensure that the shoe takes its proper form.

- Understanding the lasting process: Lasting machines are used to attach the upper to the sole while forming the shape of the shoe. These machines use heat, pressure, or a combination of both to secure the upper to the sole, making it durable and ensuring it holds its shape over time.

- Machines for molding shoe soles: Molding machines are used to create the sole of the shoe by applying heat and pressure to materials such as rubber, plastic, or leather. This process is important for creating soles that are both durable and comfortable.

3. Cutting Machines for Footwear

Cutting is a fundamental step in the shoemaking process, as it involves creating precise pieces of leather, fabric, and other materials that will form the upper and parts of the sole.

- Laser and die cutting technologies: Modern cutting machines use laser and die cutting technologies to ensure accuracy and efficiency in cutting complex patterns. These machines are programmed to cut specific shapes with minimal waste, which is crucial for reducing costs and ensuring the quality of the final product.

- Types of cutting machines: Depending on the material being used, different types of cutting machines are employed. Some are designed for leather cutting, while others are better suited for synthetic materials or textiles.

4. Shoe Assembly Machines

Once the various components of the shoe are cut and sewn, they need to be assembled into a finished product. This stage requires several machines designed to attach the upper to the sole, insert the insole, and ensure the shoe is properly formed.

- Automation in shoe assembly: Modern shoe machines can automatically assemble various shoe components, streamlining the production process. Automated machines are capable of attaching soles, inserting insoles, and ensuring the shoe is constructed precisely as per design specifications.

- Machines for inserting insoles: Some shoe machines are specialized for inserting the insole into the shoe, ensuring that the cushioning is properly aligned and secured.

The Process of Shoemaking: How Machines Are Used

1. The Role of Equipment in Shoe Manufacturing

The production of shoes begins with the careful preparation of materials. Equipment is used to handle materials like leather, synthetic fabrics, and rubber. These materials must be measured, cut, and prepared for assembly.

- Initial setup and equipment: Machines such as cutting machines and leather preparation tools are used to prepare the materials before they are shaped or sewn.

- Seamless integration of machinery in a production line: In a shoemaking factory, machinery is carefully integrated into a production line, with each machine performing a specific function. The production line is designed to maximize efficiency and ensure that all the steps of making shoes are done in the correct order.

2. From Sewing to Lasting: How Machines Contribute to Shoe Quality

The use of advanced machines ensures that shoes are produced with high precision and durability.

- Sewing machines in quality control: Sewing machines not only assist in the assembly of shoes, but they also contribute to maintaining the quality of stitching. High-quality stitching ensures that the shoe is both comfortable and durable, reducing the risk of wear and tear.

- Impact of lasting machines on shoe durability: Lasting machines ensure that the upper and sole of the shoe are securely attached, enhancing the longevity of the shoe and ensuring it maintains its shape over time.

Conclusion: Future Trends in Footwear Manufacturing Machines

The future of shoemaking machinery lies in greater automation, advanced materials, and more sustainable manufacturing practices. Emerging technologies like artificial intelligence and robotics are already playing a role in improving the efficiency of shoe machines, while eco-friendly materials are gaining traction in the footwear industry.

- Technological advancements: As technology continues to advance, shoemaking machines will become even more efficient, with new features such as smart sensors and AI integration.

- Future of footwear production: Shoe factories are increasingly adopting automated machines to reduce costs, improve accuracy, and minimize the environmental impact of shoe production.

Frequently Asked Questions (FAQs)

What are the main machines used in shoe manufacturing?

The main machines used in shoe manufacturing include sewing machines, lasting machines, cutting machines, and molding machines. These machines perform essential tasks such as stitching, shaping, and assembling the components of the shoe.

What does a lasting machine do?

A lasting machine shapes the upper part of the shoe and secures it to the sole. It uses pressure, heat, or both to ensure that the shoe takes its final form, contributing to the shoe’s durability and fit.

Can shoemaking be done by hand?

While some aspects of shoemaking can be done by hand, modern shoemaking relies heavily on machines for efficiency, precision, and mass production. However, traditional handmade shoes still exist, often crafted by artisans who use a mix of hand and machine tools.

How does a sewing machine help in shoe production?

A sewing machine is used to stitch the different components of a shoe together. It is crucial for assembling the upper to the sole and for reinforcing seams to ensure the durability of the shoe.